Bales on End Between Studs

How do we take as much carbon as we can out of the atmosphere and sequester it into our buildings?

Strawbale installation in our Strawbale ADU #1 project (photo by Alexander White)

Straw is a byproduct from the yearly harvesting process of grains like wheat, barley, oats, rye and rice. When the seed head is removed by a harvesting machine, what is left behind is the stalk containing primarily cellulous which is about 40% carbon. Typically the straw is left to biodegrade outside, burned, or used as a filler in cattle feedlots, all of which releases that carbon back into the atmosphere.

An exciting alternative is to use it in our buildings. Straw bales store about 128-165 kgC02/m3, making them one of the best ways to capture carbon from the air and store it in a building. A dense straw bale, when properly detailed and finished with a clay or lime-plaster skin, is highly fire resistant, insulative, and sound dampening while also regulating interior humidity and providing a thermal lag well suited to offset the swing from hot days to cool nights.

Straw has been used as an insulative material in buildings for centuries and straw bale buildings were invented in Nebraska in the late 1800s shortly after the invention of the mechanical baling machine. A strong and ongoing revival of their use started in the mid-90s, which you can read about in this article from The Last Straw Magazine. Much of this revival was centered on the West Coast with the foundation of the California Straw Building Association in 1996. Knowles Architect Inc is a member of CASBA along with our favorite structural engineers Verdant Structural Engineering.

We are working together with our colleagues at CASBA and VSE to advance the methods for streamlining straw bale construction in concert with more conventional building methods. In particular we want to bring strawbale into a modern, place-based design aesthetic that takes advantage of its unitary/modular nature to make beautiful, simple forms.

We count some of the founding members of the California Straw Building Association among our friends, mentors and collaborators. Our Strawbale ADU #1 project is currently under construction in Walnut Creek where we are using a technique called Bale-on-End-Between-Studs (BOEBS) first conceived by CASBA member Daniel Smith of DSA Architects and first deployed in a completed building by David Arkin and Anni Tilt of Arkin-Tilt Architects.

Bales on End Between Studs takes advantage of many of the properties of straw bales and marries them with a more conventional framing technique familiar to residential builders. Typical 2x6 studs walls are built at 24-inch on center (sometimes called “advanced framing”) with plywood sheathing and waterproofing on the exterior. From the plywood to the exterior this is a normal vapor-open construction method. On the inside, straw bales are stacked vertically and rammed between the studs. Lime or clay plaster is applied to the inside of the straw bales, creating an 18-inch thick wall.

Strawbale installation in our Strawbale ADU #1 project (photo by Alexander White)

Our interest is to incorporate this technique, with all of its benefits of carbon storage, thermal lag, fire resistance, sound absorption, and beautiful mass walls, into a modern architecture that takes full advantage of its modular nature and efficient building techniques based on typical wood frame construction modules.

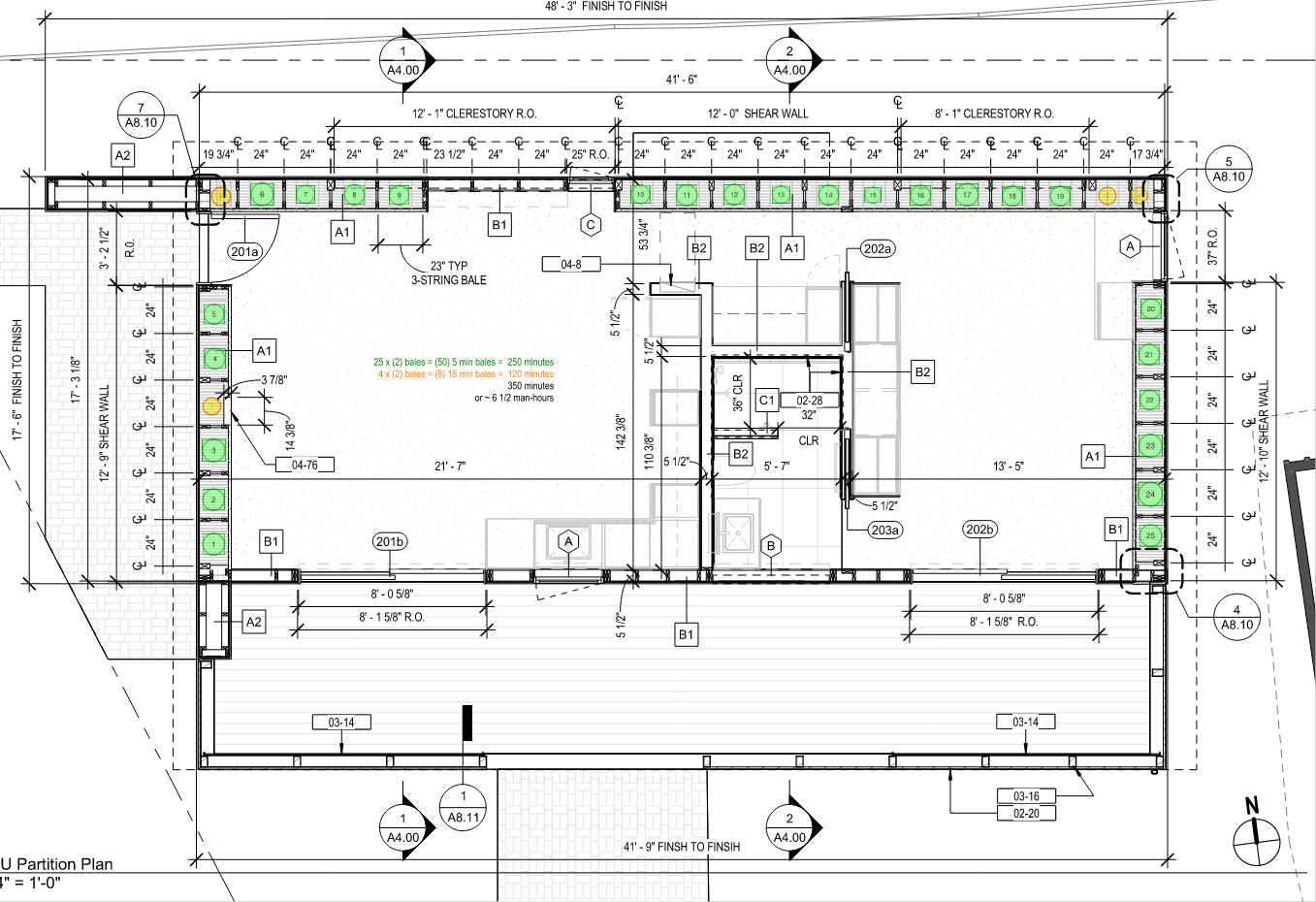

Strawbale ADU #1 floorplan with bale counts minimizing trimmed or cut bales

This starts with designing to the dimensions where bale walls and wood framing overlap. The bale portions of the wall are held to 8-feet - the height of two bales stacked on end, and the limit of a standard sheet of plywood. In plan the bale walls are long, solid masses running on a 2ft module. We cluster doors, windows, plumbing, and electrical into typically framed 2x6 portions of the wall to eliminate the complexity of incorporating those elements into the bale walls.

Strawbale installation in our Strawbale ADU #1 project (photo by Alexander White)

At the interior of BOEBS walls something is needed to hold the bales in place. Rather than use stakes or longs screws and plywood gussets we are experimenting with a second 2x4 layer of interior studs installed after the bales are already in place and the gaps between them stuffed. This not only sticks to simple framing that any rough carpenter is familiar with, it gives us a typical framing element to attach lathe and makes it easier to create a flat vertical plane on the interior.

Wherever a bale wall stops, either at the ends or the top, we are cladding that face of the wall in a maple plywood panel instead of wrapping the plaster around the side of the wall. This eliminates one of the most labor-intensive parts of plastering (rounded corners) and gives us a clean, straight edge to plaster up against. By extending the plywood “casing” slightly beyond the face of the wall we also protect the corner and hide a plaster shrinkage joint in a kerf.

Strawbale installation in our Strawbale ADU #1 project (photo by Alexander White)